The OpFlow success goes coast-to-coast! Loma Linda University Medical Center just completed phase 1 of OpFlow Instrument Tray Optimization with a total reduction of over 4,000 instruments!

The scope for this initial phase included Orthopedics, Neurosurgery, Cardiac and Vascular Surgery service lines.

That 31% instrument reduction on trays from those 4 service lines alone will result in a decrease of over 297,000 instruments that need to be sterilized each year.

Check out the photos of the Neuro Instruments Set that OpFlow was able to reduce by 25.9% using our clinically-guided, data-driven approach!

Thank you, Loma Linda University Health, for a great start on your tray optimization journey and we are looking forward to starting the next phase with your General Surgery, Urology, OB/GYN, ENT and Plastic Surgery service lines!

Another OpFlow success! Congrats to Piedmont Atlanta Hospital for completing a total reduction of 31% across 5 major service lines!

“As a not-for-profit healthcare system, we must be good stewards of our valuable resources that enable us to provide high-quality, patient-centered care. One of my main objectives is to run a highly effective and efficient operation with a focus on the elimination of waste. The complex operations of Piedmont Atlanta hospital required a sophisticated partner to support us in a tray rationalization project.

The team at OpFlow exceeded our expectations! We were able to remove 7,500 instruments with an average reduction percentage of 31%. This will lead to almost 500,000 fewer instrument sterilization cycles annually, saving over 2,300 hours of sterile processing labor.”

- Josh Roberts

Chief Operating Officer

Piedmont Atlanta Hospital

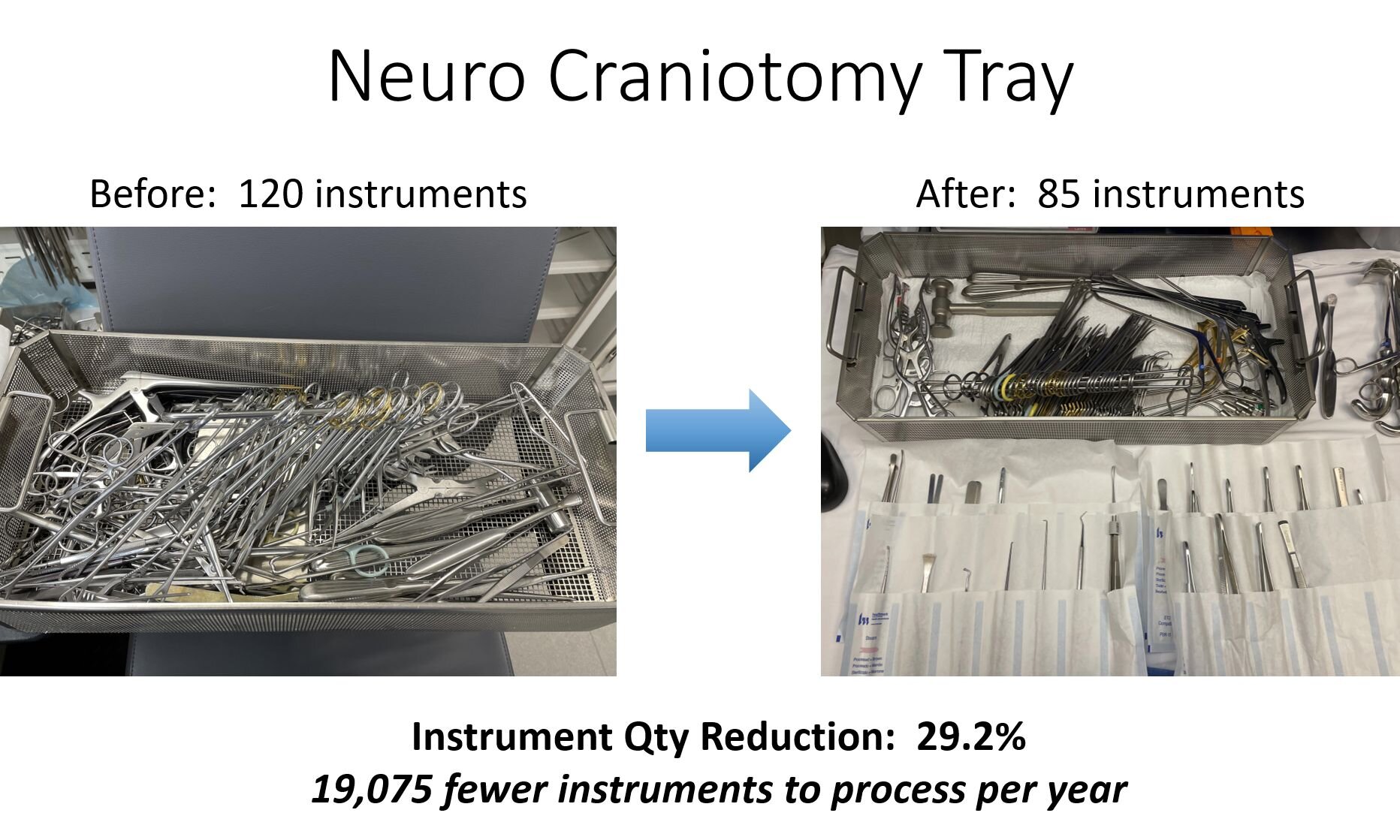

Here are examples of the instrument tray reductions that were achieved for the Neurosurgery service line at Piedmont:

Completion of a 12-month implementation of OpFlow at UNC Rex Hospital spanning all major surgical services lines resulted in an overall reduction of 17,936 instruments!

1. Based on UNC Rex Hospital internally validated mean per instrument sterile processing cost.

2. Average assembly (decontamination, packing) time 12.5-17.7s per instrument: John-Baptiste A, et al. CMAJ Open. 2016 Aug;4(3):E404-E408.

3. Fair market value utilized for instrument re-purchase cost when direct pricing information unavailable.